On 7 October 2020, we have successfully marked the 5th General Assembly meeting of CHESTER project during its third year (currently M31). Exceptionally, the meeting was held online to respect the current measures due to the COVID-19 health crisis. The virtual gathering was a key moment to showcase the project progress for the past months.

More than 25 members of the consortium from all 12 partners gathered online to mark the momentum the project has gained during its third year. The meeting started with a brief welcoming address from the coordinator Tecnalia and a project overview for the most urgent topics on the agenda. An action plan for the next steps has been outlined with regards the pending deliverables that were impacted due to the work and travel restrictions of the global health pandemic for the last 8 months. Risk and contingency plans were also presented for each work package to ensure the project will run smoothly.

ACHIEVEMENTS:

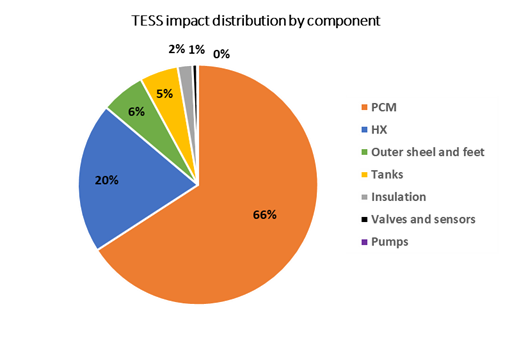

- WP3 Ground-breaking advancements on individual technologies led by Tecnalia highlighted that although the unplanned delays due to COVID-19, the important milestones were successfully achieved. Almost all technologies have proved to work properly fulfilling the project objectives set in the implementation plan.

- WP4 Full Scale CHEST system and smart control algorithms presented by Aiguasol and USTUTT showed through the results of comprehensive simulation studies how the performance of the CHEST system can be improved by, for instance, more suitable combinations of PCMs and refrigerants and the implementation of optimized control strategies

- WP5 First-of-its-kind CHEST prototype demonstration with DLR as leader outlined that the laboratory space is completely prepared for the integration, as well as the preliminary installation of the heat source and sink are completed.

- WP6 Market and business opportunities assessment led by PlanEnergi, concluded that the CHEST technology can find future market realisation and provide energy savings in the highly electrified system where heat is produced predominantly in electric heat pumps driven by Renewable Energy Sources. In parallel, Aiguasol is further progressing on the development of the open-source tool which enable a wide range of users to estimate the CHEST potential for both grid-connected and standalone systems.

- WP7 Dissemination, exploitation and communication presented by PNO Innovation emphasises on the better understanding of the stakeholders´ perceptions and attitudes towards CHEST technology, the identification of potential hurdles to market update of the technology, as well as pinpointing organisations with exploitation interest. A valuable input for enhancing the communication and dissemination strategy was also made.

Each partner presented the most important achievements for the respective work package and what lay out the next steps:

CONCLUSIONS:

In the late afternoon, the General Assembly meeting continued with two parallel sessions that covered the following topics:

- Integration requirements and control of CHEST technology (DLR, Tecnalia, ECT, UPV) – DLR announced they are expecting to receive the Heat Pump and ORC prototypes in their laboratories by mid-November. Integration of prototypes and testing of the PCM can be made in parallel. DLR will also organize additional meetings to discuss the next steps about the prototype integration, the control, and special technologies before the commissioning.

- Techno-economic perspective of CHEST technology (PlanEnergi, GoiEner, Aiguasol, Iren, USTUTT, Tecnalia, PNO) – Nowadays, there are no business opportunities for storage technologies, however, the market is about to change in the upcoming years. The market shift will increase the need for the flexibility in the network due to rise of the renewable energy.According to our analysis, CHEST technology has higher unit investment costs per installed capacity in comparison to conventional batteries. However, the lower expected lifetime of the conventional batteries (about 10-15 years) compared with CHEST technology (average 30 years lifespan), makes the investment into the batteries comparable or in some cases, such us an island mode operation, even more expensive. Therefore, CHEST technology will be more beneficial option and a better economic solution from the current batteries on the market, when an independence from the Distribution system operators is achieved. This benefit gets even more pronounced for larger storages.

The next General Assembly meeting will be held in April 2021 (M36) and if the situation allows it will take place in DLR’s perimeters in Stuttgart, Germany.